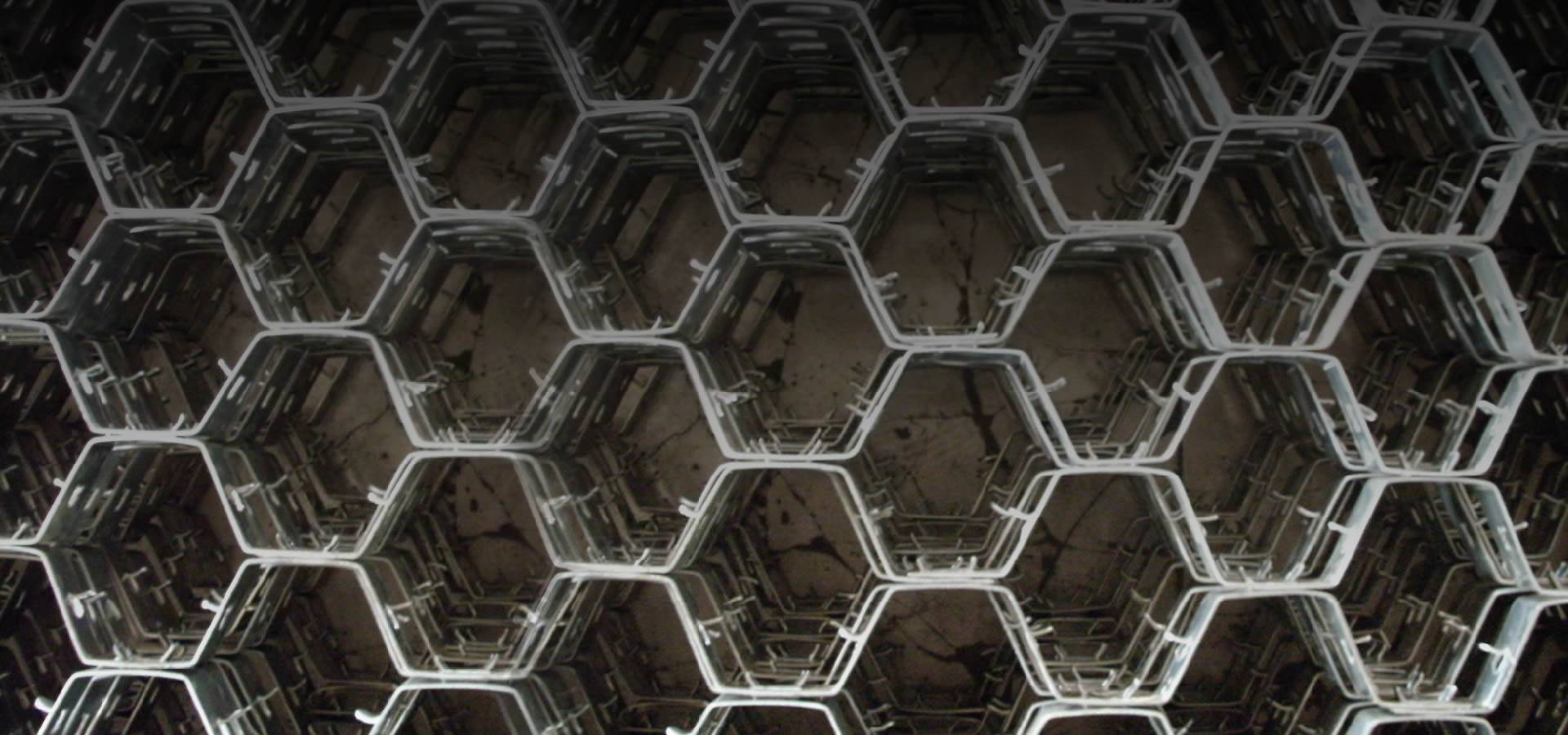

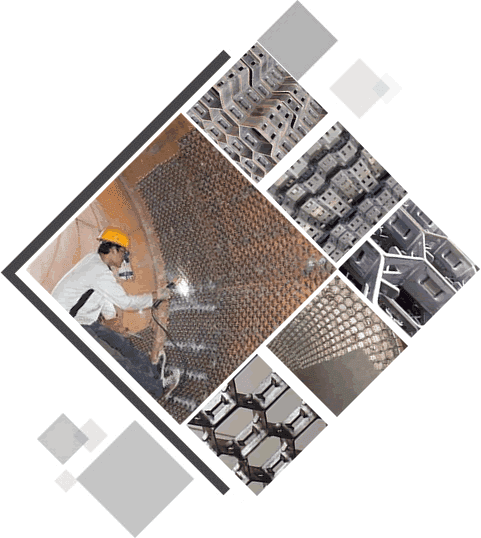

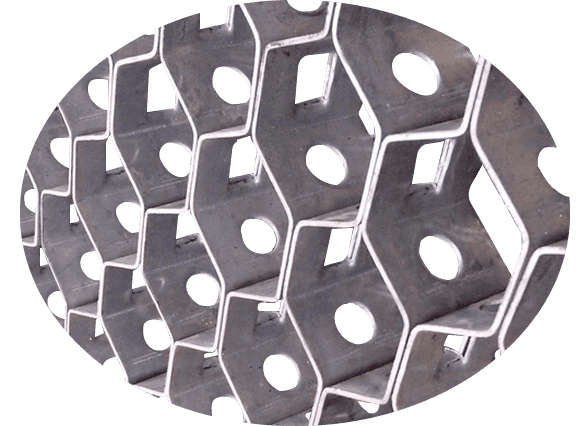

Refractories are material having high melting points, with properties that make them suitable to act as heat-resisting barriers between high and low temperature zones. Refractories are useful in constructing application- specific high temperature areas or surfaces, particularly in furnaces or boilers, as they minimize heat losses through structure.

Lining refers to permanent support structure that to prevent deformation or collapse of surrounding rock. It is the construction of reinforced concrete and other materials that builds along the surrounding of tunnel body.